Inquiry

Please do not hesitate to contact us for further information, quotations, etc.

T&D Center

Being among the leaders of the industry, we work hard to develop new forming technologies at our T&D center and produce ERW pipe mills that not just meet, but go one step ahead of the needs of the world today.

FEM Simulation

Nakata introduced proprietary 3D plastic/elastic forming analysis technology to the world as our answer to what we identify as the overreliance on workers’ intuition and skills with cold forming pipe techniques. Our goal is to remove the element of human error, while providing a steady supply of pipe-forming solutions, regardless of workers’ experience levels.

We have endeavored to this day with the greatest mission of “invention and development of better forming technology”. At our T&D center we developed 3-dimensional plastic/elastic FEM analysis technology and applied it to create the FFX Mill, backed by theoretical and scientific analysis. As the leader of the industry, we pursue new forming technologies for tomorrow’s challenges, as well as upgrading existing technologies to develop ERW mill machines that meet today’s tough requirements.

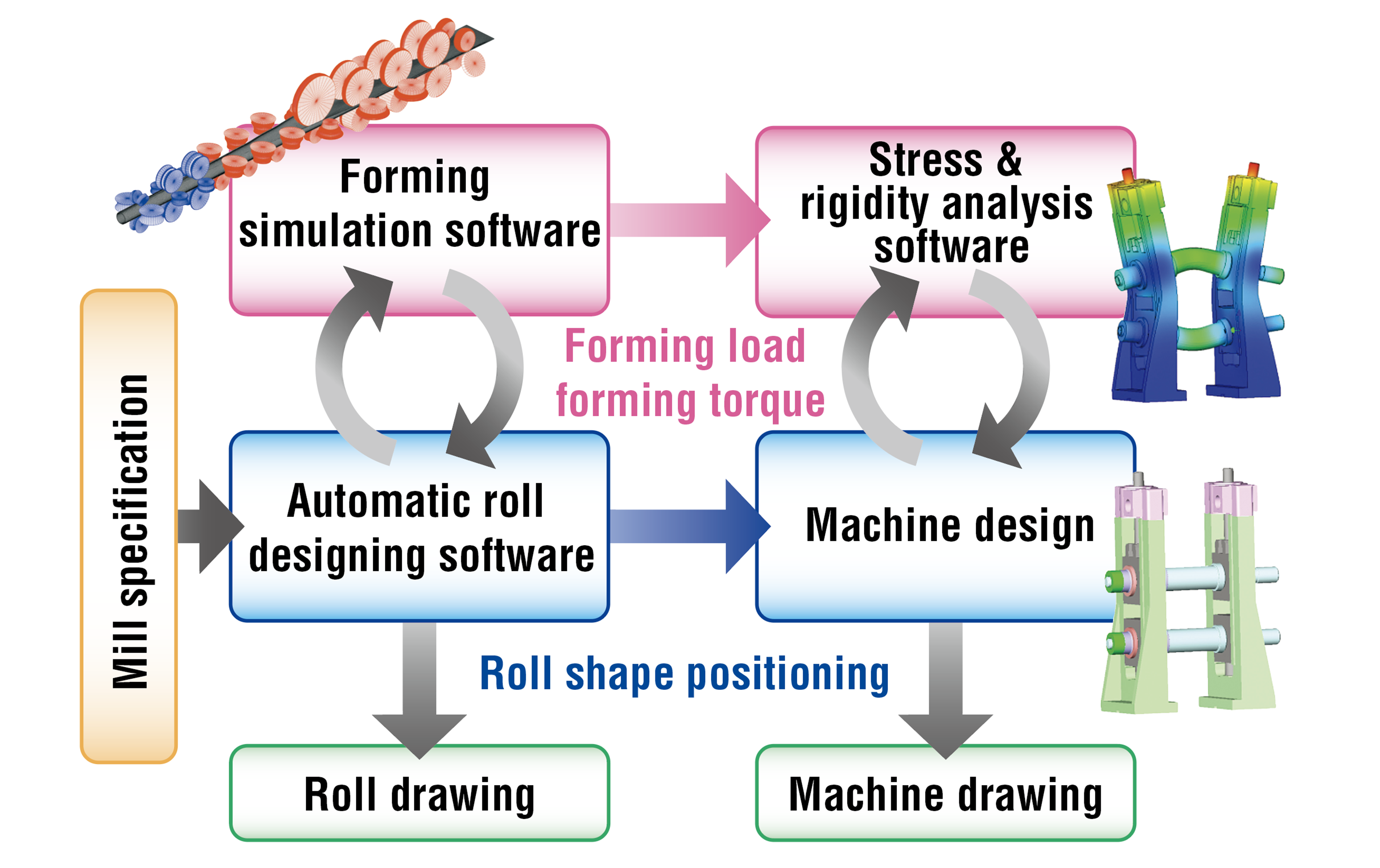

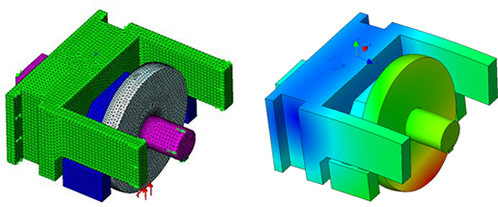

At our T&D center we custom design rolls and their positioning using our forming analysis programs. Next, the design department finalizes the machine design by considering the roll design received from the T&D center and applying structural analysis programs. Data, such as forming loads, obtained from forming analysis sofware, are used as the boundary condition to ensure rational design with perfect fit to customer’s needs. Such Computer Aided Engineer System (CAE) allows the incorporation of variuos NAKATA’s technologies in the ERW pipe making lines that we deliver to our customers.

Up until now, pipe forming was entrusted to the experience and skills of mill operators. The forming of ERW pipe involves complex 3-dimensional plastic/elastic deformations and there is a limit to understanding such profound processes of deformation behaviors, stress and strain when relying solely on skills of experienced workers. It was also impossible to evaluate a mill design unless actually conducting forming process in reality. The optimization of process was extremely difficult for this reason, requiring many design corrections and modifications after building the mill.

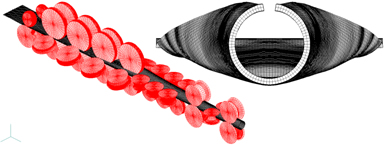

NAKATA’s proprietary 3D plastic/elastic forming analysis system makes it possible for us to scientifically and theoretically understand the complex behaviors of the steel strip during the forming process. We built our own roll forming simulation system to accurately predict strip deformation under roll stress. With these tools, we have made it possible to optimize forming processes on computer.

Simulation system on computer monitor

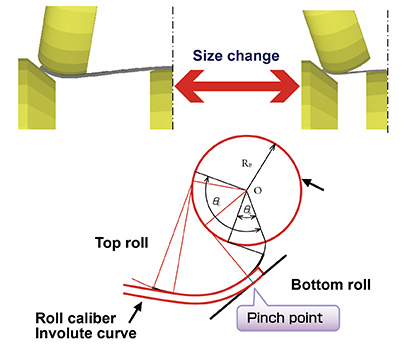

NAKATA developed an ideal forming method using involute curvature rolls (FF rolls) by applying FEM analysis technology. This revolutionary method not only eliminated the need for roll change, but also minimized influences of diameter, material thickness and steel type while determining the best edge butt shape. The FFX mill is capable of manufacturing high grade pipes such as X80 and N80.

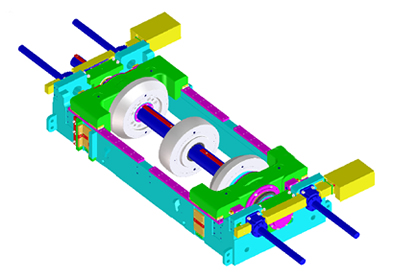

Support for mechanical design

FEM forming analysis translates forming loads into high accuracy data. By applying FEM structural analysis based on the data, optimized mechanical structure is designed. In addition NAKATA’s know-how is incorporated in creating high rigidity cross beam structure for the mills. In our new design, cross beams in the main frame support forming loads which were traditionally held up by the mill shaft. The new cross beam design helps to achieve high mill rigidity. Design assistance for square pipe forming machines Normally, the formation of round pipes into shaped ones requires more stands and roll groups. FEM analysis technology helps with roll-sharing (with involute curvature) and reducing roll changes, while making all-roll-drive increases thrust power and stabilizes the line. This is an example of how Nakata’s FEM analysis software helps to introduce new and unique pipe-forming solutions to the industry.

NAKATA’s FEM analysis technology has a high success rate improving product quality and yield of conventional type mills.